How to Choose the Right Dry Underfloor Heating System

Dry underfloor heating systems come in various forms, but

not all deliver the same level of performance, durability, or ease of

installation. Here’s what to consider when selecting the right system for your

project.

1. Panel Material

- Wood:

heavy, expensive, and absorbs moisture.

- Gypsum:

heavy and fragile – cracks of the panels can lead to lose the whole board.

- ASSENS

EPS400 Polystyrene: is the smart choice because the panels are

ultra-lightweight, moisture-resistant, and feature aluminum foil that

blocks oxygen, UV rays and humidity.

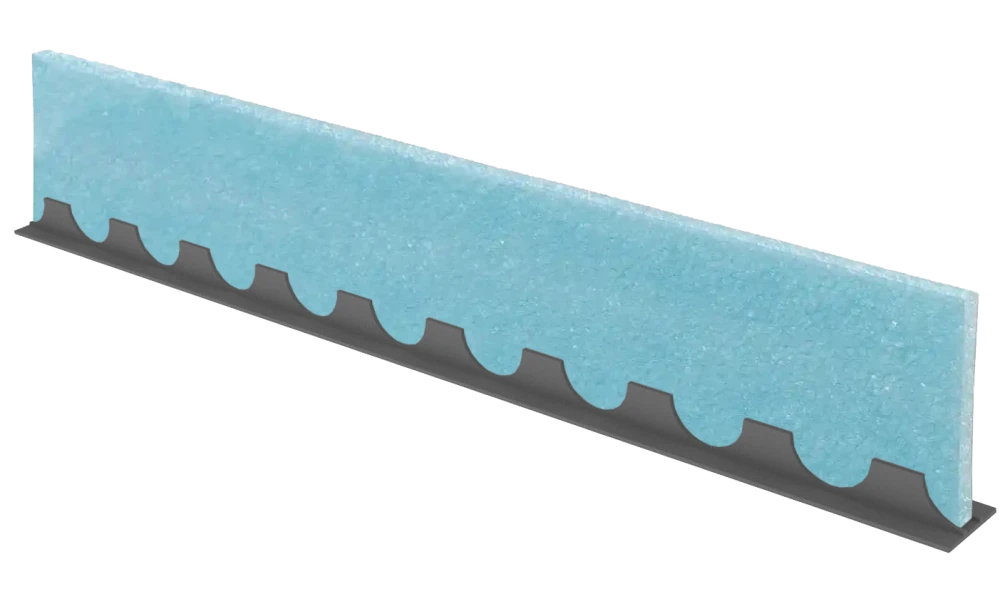

2. Preformed Channels vs. Flat Panels

- Flat

panels require special tools to carve channels, increasing labor and time.

- ASSENS

EPS400 panels come with pre-cut straight and rounded channels, so only one

panel is needed for full system installation.

3. Thermal Efficiency

The aluminum foil layer acts as a radiator, distributing

heat evenly across the floor surface by absorbing and radiating warmth from the

heating pipes.

4. Channel Design

Basic panels often require separate return panels for pipe

turns. In contrast, ASSENS EPS400 panels include built-in turning channels,

simplifying installation and logistic—no need for multiple panel types.

5. Panel Density

- EPS200:

lower density, requires a load-distribution membrane, adding cost and

complexity.

- EPS400:

high-density, no membrane needed, saving both time and money.

6. Compatibility with Floor Finishes

EPS400 panels can be used with screed, parquet, tiles, or

marble. Adhesives or leveling compounds can be applied underneath or on top as

needed—just ensure your top layer is compatible with underfloor heating.

Conclusion:

For a reliable, efficient, and easy-to-install dry system, ASSENS EPS400 panels

offer the best solution: one panel, multiple advantages, no compromises.

The pre-assembled 250 MPa hydroformed stainless steel manifold consists of a supply bar and a return bar with 1" internal thread. The supply bar and return bar are mounted with a sound-absorbing element on the brackets.

The supply bar contains:

·

flow regulators

(displayed value 0 - 5l/min) for accurate flow regulation without tools. The

flow volume can be read through the transparent inspection glass,

·

2 to 12 nickel-plated outlets with 3/4“ euroconus thread

·

1 set of nickel plated

1/2" fill/drain valves with manual air vent.

The return bar contains:

·

thermostatic valves for actuators (M30 x 1.5mm, valve stroke

2.9mm) with protective caps,

·

2 to 12 nickel-plated outlets with 3/4" euroconus thread

·

1 set of nickel plated 1/2" fill/drain valves with

manual air vent.

Maximum

operating temperature Tmax: 70°C

Maximum

operating pressure Pmax: 0.6 MPa (6 bar).

Kvs coefficient: Nomograms no. 314/1209/19/3,4,5 and 6

In

their current configuration, underfloor heating systems appear at the beginning

of the 20th century. The English professor Baker is the first to obtain a

patent entitled "System of heating premises with hot water carried through

pipes under the floor". The actual development of the system takes place

immediately after World War II, with the reconstruction campaign in Europe.

The most important benefits of underfloor heating are the following:

·

Provides comfortable and even warmth underfoot, eliminating cold

spots and drafts

·

It operates at a lower temperature than traditional

radiators, reducing energy consumption and utility bills.

·

It is more hygienic as it prevents dust mites and mold growth

·

It saves space and allows more flexibility in furniture placement

as there are no radiators on the walls.

· Can be used with most floor surfaces and divided into zones for increased comfort

A

manifold for underfloor heating system is among the most important element of

the entire system. It is a multi-functional alternative that helps to perform

the assembly steps efficiently. Its main role is to control temperature, flow

and implicitly to reduce maintenance costs.

Flow meter glass material: natural EMS

Grilamid TR55 that offers UV and LX protection

Flow meter spring material: stainless steel