Why Perimeter Edge Strips Matter in Underfloor Heating Systems

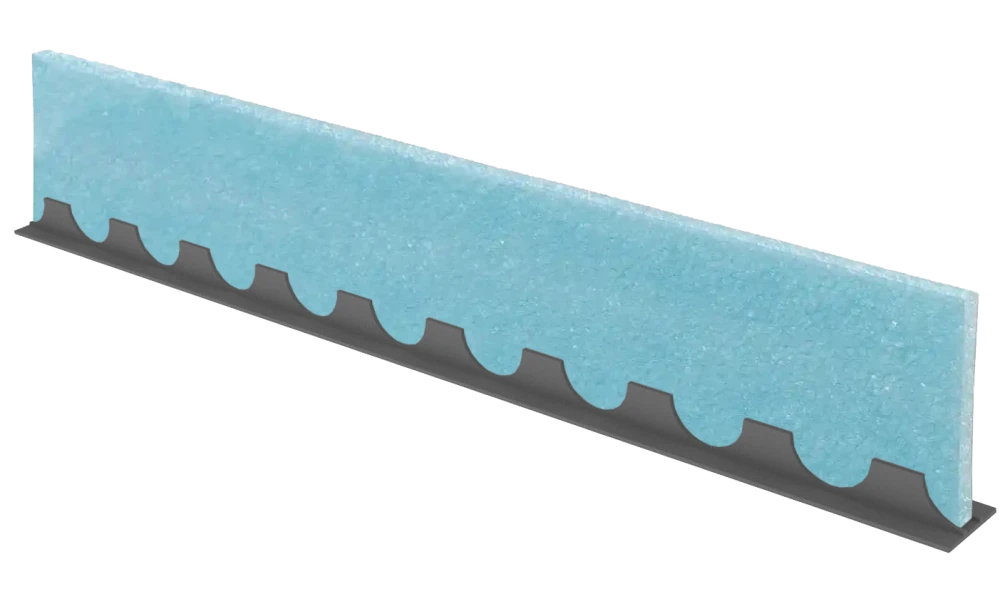

A small but essential component in any wet underfloor

heating system is the perimeter edge strip. While often overlooked, this

element plays a critical role in the performance and stability of the floor.

What is a perimeter edge strip?

It’s a flexible insulating strip installed along the base of

interior and exterior walls, between the screed and the wall. Its main role is

to absorb lateral expansion of the screed and prevent heat and sound transfer

to adiacent structures.

Why is it necessary?

- ✅

Allows screed expansion – prevents pressure buildup against walls and

reduces risk of cracks.

- ✅

Minimizes thermal bridges – reduces heat loss through uninsulated wall

areas.

- ✅

Improves acoustic insulation – limits sound transmission through the floor

structure.

- ✅

Protects floor finishes – prevents stress or damage along floor edges over

time.

Where is it installed?

- Along

all walls (interior and exterior), and around columns or vertical elements

- Installed

before screeding, directly above the insulation layer

Conclusion:

The perimeter edge strip is a must-have in any wet underfloor heating system.

It enhances thermal and acoustic efficiency while protecting your flooring

investment long-term.

The pre-assembled 250 MPa hydroformed stainless steel manifold consists of a supply bar and a return bar with 1" internal thread. The supply bar and return bar are mounted with a sound-absorbing element on the brackets.

The supply bar contains:

·

flow regulators

(displayed value 0 - 5l/min) for accurate flow regulation without tools. The

flow volume can be read through the transparent inspection glass,

·

2 to 12 nickel-plated outlets with 3/4“ euroconus thread

·

1 set of nickel plated

1/2" fill/drain valves with manual air vent.

The return bar contains:

·

thermostatic valves for actuators (M30 x 1.5mm, valve stroke

2.9mm) with protective caps,

·

2 to 12 nickel-plated outlets with 3/4" euroconus thread

·

1 set of nickel plated 1/2" fill/drain valves with

manual air vent.

Maximum

operating temperature Tmax: 70°C

Maximum

operating pressure Pmax: 0.6 MPa (6 bar).

Kvs coefficient: Nomograms no. 314/1209/19/3,4,5 and 6

In

their current configuration, underfloor heating systems appear at the beginning

of the 20th century. The English professor Baker is the first to obtain a

patent entitled "System of heating premises with hot water carried through

pipes under the floor". The actual development of the system takes place

immediately after World War II, with the reconstruction campaign in Europe.

The most important benefits of underfloor heating are the following:

·

Provides comfortable and even warmth underfoot, eliminating cold

spots and drafts

·

It operates at a lower temperature than traditional

radiators, reducing energy consumption and utility bills.

·

It is more hygienic as it prevents dust mites and mold growth

·

It saves space and allows more flexibility in furniture placement

as there are no radiators on the walls.

· Can be used with most floor surfaces and divided into zones for increased comfort

A

manifold for underfloor heating system is among the most important element of

the entire system. It is a multi-functional alternative that helps to perform

the assembly steps efficiently. Its main role is to control temperature, flow

and implicitly to reduce maintenance costs.

Flow meter glass material: natural EMS

Grilamid TR55 that offers UV and LX protection

Flow meter spring material: stainless steel