Testing water installations has never been easier. ASSENS test plugs provide a quick and reliable way to seal pipes when sanitary fittings or other accessories are not yet installed – saving time and preventing costly leaks.

Made from durable polypropylene and equipped with EPDM gaskets, these plugs always ensure a secure and efficient seal. Installation is simple – tighten by hand or with a wrench – and the color-coded design (red for hot water, blue for cold water) allows for quick pipe identification.

Available in 1/2" sizes, the plugs are ideal for heating and domestic water systems, offering professionals an efficient and precise solution for leak testing.

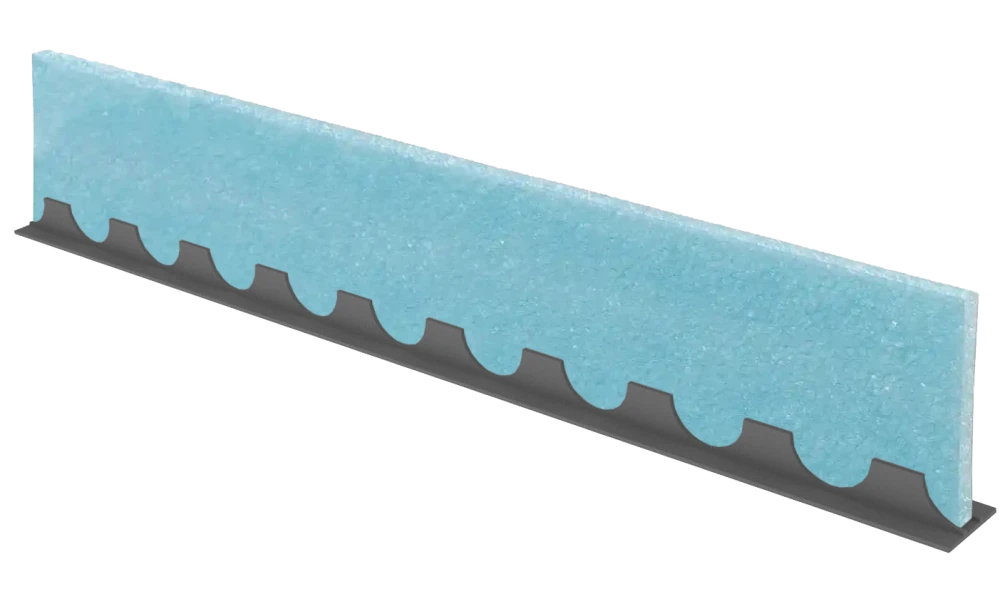

A small but essential component in any wet underfloor

heating system is the perimeter edge strip. While often overlooked, this

element plays a critical role in the performance and stability of the floor.

What is a perimeter edge strip?

It’s a flexible insulating strip installed along the base of

interior and exterior walls, between the screed and the wall. Its main role is

to absorb lateral expansion of the screed and prevent heat and sound transfer

to adiacent structures.

Why is it necessary?

- ✅

Allows screed expansion – prevents pressure buildup against walls and

reduces risk of cracks.

- ✅

Minimizes thermal bridges – reduces heat loss through uninsulated wall

areas.

- ✅

Improves acoustic insulation – limits sound transmission through the floor

structure.

- ✅

Protects floor finishes – prevents stress or damage along floor edges over

time.

Where is it installed?

- Along

all walls (interior and exterior), and around columns or vertical elements

- Installed

before screeding, directly above the insulation layer

Conclusion:

The perimeter edge strip is a must-have in any wet underfloor heating system.

It enhances thermal and acoustic efficiency while protecting your flooring

investment long-term.

In a wet underfloor heating system, dilatation profiles are

not just a recommendation – they’re critical for the performance and structural

integrity of the installation.

What are dilatation profiles?

These are separation elements placed in the screed that

allow the floor to expand and contract naturally as temperatures change.

Without them, the screed may crack and deform, potentially damaging the heating

system and the finishes of the floor.

Why are they so important?

- ✅

Prevent screed cracking – thermal expansion creates internal stresses; dilatation

profiles absorb and relieve them.

- ✅

Protect heating pipes – structural movement can stress or damage the

embedded pipes.

- ✅

Ensure even system performance – no deformation, no heat loss, no risk to

efficiency.

- ✅

Divide large areas – essential for rooms over 8 m long or 40 m² in total

surface.

Where and how are they installed?

- At

door thresholds or room transitions

- Every

8 linear meters in large open spaces

- Installed before screeding, directly over insulation and between heating pipe circuits

Conclusion:

Dilatation profiles are a key detail in wet underfloor heating systems. They

protect your investment by ensuring durability, efficiency, and safe operation

over time.

Dry underfloor heating systems come in various forms, but

not all deliver the same level of performance, durability, or ease of

installation. Here’s what to consider when selecting the right system for your

project.

1. Panel Material

- Wood:

heavy, expensive, and absorbs moisture.

- Gypsum:

heavy and fragile – cracks of the panels can lead to lose the whole board.

- ASSENS

EPS400 Polystyrene: is the smart choice because the panels are

ultra-lightweight, moisture-resistant, and feature aluminum foil that

blocks oxygen, UV rays and humidity.

2. Preformed Channels vs. Flat Panels

- Flat

panels require special tools to carve channels, increasing labor and time.

- ASSENS

EPS400 panels come with pre-cut straight and rounded channels, so only one

panel is needed for full system installation.

3. Thermal Efficiency

The aluminum foil layer acts as a radiator, distributing

heat evenly across the floor surface by absorbing and radiating warmth from the

heating pipes.

4. Channel Design

Basic panels often require separate return panels for pipe

turns. In contrast, ASSENS EPS400 panels include built-in turning channels,

simplifying installation and logistic—no need for multiple panel types.

5. Panel Density

- EPS200:

lower density, requires a load-distribution membrane, adding cost and

complexity.

- EPS400:

high-density, no membrane needed, saving both time and money.

6. Compatibility with Floor Finishes

EPS400 panels can be used with screed, parquet, tiles, or

marble. Adhesives or leveling compounds can be applied underneath or on top as

needed—just ensure your top layer is compatible with underfloor heating.

Conclusion:

For a reliable, efficient, and easy-to-install dry system, ASSENS EPS400 panels

offer the best solution: one panel, multiple advantages, no compromises.

Testing water installations has never been easier. ASSENS test plugs provide a quick and reliable way to seal pipes when sanitary fittings or other accessories are not yet installed – saving time and preventing costly leaks.

Made from durable polypropylene and equipped with EPDM gaskets, these plugs always ensure a secure and efficient seal. Installation is simple – tighten by hand or with a wrench – and the color-coded design (red for hot water, blue for cold water) allows for quick pipe identification.

Available in 1/2" sizes, the plugs are ideal for heating and domestic water systems, offering professionals an efficient and precise solution for leak testing.

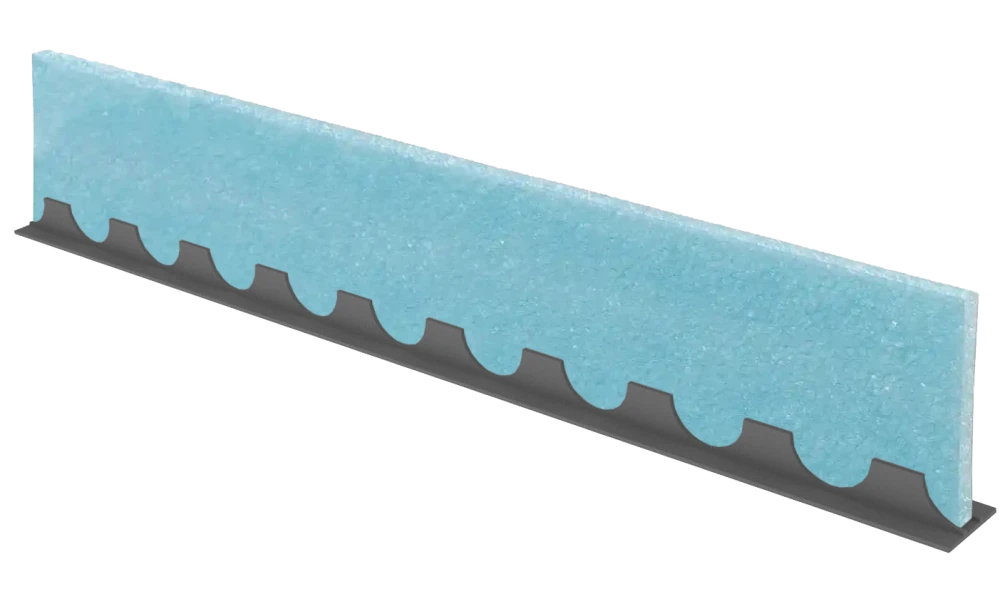

A small but essential component in any wet underfloor

heating system is the perimeter edge strip. While often overlooked, this

element plays a critical role in the performance and stability of the floor.

What is a perimeter edge strip?

It’s a flexible insulating strip installed along the base of

interior and exterior walls, between the screed and the wall. Its main role is

to absorb lateral expansion of the screed and prevent heat and sound transfer

to adiacent structures.

Why is it necessary?

- ✅

Allows screed expansion – prevents pressure buildup against walls and

reduces risk of cracks.

- ✅

Minimizes thermal bridges – reduces heat loss through uninsulated wall

areas.

- ✅

Improves acoustic insulation – limits sound transmission through the floor

structure.

- ✅

Protects floor finishes – prevents stress or damage along floor edges over

time.

Where is it installed?

- Along

all walls (interior and exterior), and around columns or vertical elements

- Installed

before screeding, directly above the insulation layer

Conclusion:

The perimeter edge strip is a must-have in any wet underfloor heating system.

It enhances thermal and acoustic efficiency while protecting your flooring

investment long-term.

In a wet underfloor heating system, dilatation profiles are

not just a recommendation – they’re critical for the performance and structural

integrity of the installation.

What are dilatation profiles?

These are separation elements placed in the screed that

allow the floor to expand and contract naturally as temperatures change.

Without them, the screed may crack and deform, potentially damaging the heating

system and the finishes of the floor.

Why are they so important?

- ✅

Prevent screed cracking – thermal expansion creates internal stresses; dilatation

profiles absorb and relieve them.

- ✅

Protect heating pipes – structural movement can stress or damage the

embedded pipes.

- ✅

Ensure even system performance – no deformation, no heat loss, no risk to

efficiency.

- ✅

Divide large areas – essential for rooms over 8 m long or 40 m² in total

surface.

Where and how are they installed?

- At

door thresholds or room transitions

- Every

8 linear meters in large open spaces

- Installed before screeding, directly over insulation and between heating pipe circuits

Conclusion:

Dilatation profiles are a key detail in wet underfloor heating systems. They

protect your investment by ensuring durability, efficiency, and safe operation

over time.